Winning the Food Waste Battle

More Food Waste Coverage

Addressing the food waste crisis is more important than ever. Sixty-three million pounds of food is thrown away annually in the United States alone, reaching landfills and contributing up to 10% of greenhouse-gas emissions globally, according to impact technology company Divert Inc. More than 40% of food loss occurs at the retail and consumer level, and the average grocery store loses $40,000 in profit a month on wasted food.

“Food retailers sit in a unique position within the food supply chain and have a critical role to play in mitigating wasted food,” says Ryan Begin, co-founder and CEO of Concord, Mass.-based Divert. “In doing so, they can see significant cost savings, provide food to communities in need, meet their social and environmental goals, and help to ensure the future of our planet.”

While many food retailers already take part in food donation programs, there are plenty of sustainability partners that can help grocers explore other business-savvy strategies to divert food waste from landfills. Here are just a few suggestions.

Put to Good Use

Specialty waste and environmental services company Denali works with retailers to build a food waste recycling strategy that delivers the most impact against their shrink and diverts unsold and inedible food from landfills.

“For example, Denali’s technology can efficiently separate food from packaging so items like potato chips or bread can be converted into valuable animal feed,” explains Todd Mathes, CEO of Russellville, Ark.-based Denali, which “also has a process to extract oil from semi-liquid products like salad dressing and mayonnaise to make biodiesel. From there, what can’t go to animals or fuel, we make into compost.”

Annually, the company recycles hundreds of thousands of tons of food waste from more than 10,000 grocery stores into materials such as animal feed, fertilizer and renewable fuels, enabling grocers to support the circular economy.

Denali experienced great success with retailers last year. “First, we successfully expanded the types of food waste we can accept from one of the largest grocers in the U.S.,” says Mathes. “We worked closely with the grocer to apply a new process so that deli waste, which requires special handling because it contains meats, could be combined with other types of food waste to produce renewable natural gas. This innovation helped them reduce their food waste footprint across dozens of locations and prevented a large amount of food from going to landfills.”

Denali is also providing more data to its grocery partners so they can address food waste at the source. “This data is helping retailers to look across their internal processes for opportunities to optimize purchasing, reducing both shrink and food waste,” says Mathes. “For example, the data has empowered a grocer in the southwest U.S. to change procurement and in-store strategies. As a result, we’re handling less food waste from their stores because the retailer is creating less food waste.”

Actionable Data

Divert is also a big believer that actionable data can be an incredibly powerful tool to prevent wasted food.

“Retailers need to know what food is going to waste, how much and why it’s happening,” explains Begin. “Collecting actionable information, such as time on shelf and the temperature food is kept at, is important in order to build awareness and make changes to prevent wasted food long term. Understanding how often and why food goes to waste can inform future purchase orders and unlock new supply chain efficiencies.”

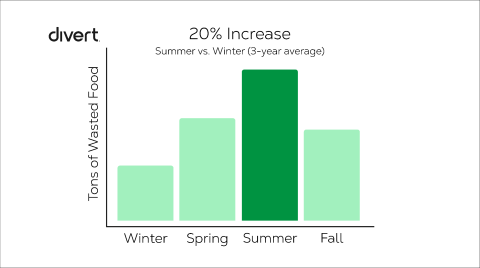

Further, did you know that grocers waste more food during the summer? New data from Divert found that wasted food from grocery stores increases by an average of nearly 20% during the summer versus the winter (see the chart below).

“Summer marks peak growing season across the U.S.,” notes Begin. “While this is a time to celebrate an abundance of fresh produce and gather with our family and friends, our data indicates that the summer is also a period when a significant amount of that produce goes to waste.”

The company looked at wasted food processed at its facilities across the nation in 2020-22 during July through September compared with January through March. In its analysis of what’s contributing to the drastic increase, the company identified such key factors as:

Peak Produce Season: An increased abundance of produce during the summer translates to a greater volume coming into grocery stores. In addition to a greater selection, more fresh food can go to waste if it’s not moved and sold quickly enough. Technologies like artificial intelligence and Internet of Things solutions can be used to identify trends or issues in stores, and uncover insights that can inform food retailers’ future processes to prevent unnecessary waste.

Heat and Human Error: When produce is exposed to greater temperature fluctuations like those seen during the summer, the percentage of wasted food increases for retailers. In the heat of the summer, produce left on a retailer’s loading dock for too long before being moved into a cooler can cause it to lose freshness more quickly. When that food goes home with the consumer, it then lasts for fewer days in the fridge. Divert suggests that increased awareness and appropriate training of retail employees led by data-driven insights could help to address this.

In addition, Divert can process wasted food into alternative energy resources. “One of the most sustainable solutions is a process called anaerobic digestion, which turns wasted food into renewable energy,” says Begin. “In doing so, retailers can help recoup some of the value that went into producing that food — from the water and energy that went into producing it, to the people and transportation that went into bringing it to a store shelf. In the case of Divert, our anaerobic digestion process produces renewable energy considered to be carbon negative. It can be used to supply homes and businesses, or utilized by retailers at their own facilities, like in the case of our Freetown, Mass., facility, where it powers up to 40% of Stop & Shop’s distribution center.”

Organics Recycling

When it comes to organics recycling, many people assume that it simply means organics composting, according to Cameron Funk, chief sustainability officer at Dallas-based CheckSammy, a waste removal, recycling and sustainability services company. While composting is one possible part of the equation, it’s not the whole story.

“CheckSammy’s nationwide network of 25,000 haulers and sustainability-focused facilities includes places such as anaerobic digestion facilities that enable us to take organic materials and dispose or redirect them sustainably,” says Funk. “We serve as a one-call solution to provide collection, sorting and recycling services.

“Whether you have a one-time need or require regularly scheduled pickup services and an on-site container, CheckSammy provides detailed analytics quantifying the complete chain of custody for your sustainability and ESG compliance. It’s a full-circle sustainability solution in one place,” he continues.

Further, the scale of CheckSammy’s sustainability network — its facilities are spread across North America — allows the company to minimize the distance traveled from grocers’ locations to an end-of-life facility.

In January, the company broadened its sustainability offerings with the CheckSammy Carbon Offset Marketplace to help companies efficiently implement short- and long-term carbon offset strategies. Carbon credits, also known as carbon offsets, are permits that allow the owner to emit a certain amount of carbon dioxide or other greenhouse gases. As brands work on their long-term decarbonization initiatives, they can now purchase carbon credits online to accelerate their positive climate impact.

The Carbon Offset Marketplace launched in partnership with South Pole, a global provider of climate financing and developer of verified emission-reduction projects. CheckSammy’s marketplace supports global carbon reduction across biodiversity- and nature-based solutions like wind and waste-to-energy projects. This drives measurable emission reductions and results in critical socio-economic co-benefits.